Home :: Part Handlings Aids ::: Mould Shield

Mould Shield

Code:PS-3447

-

Mouldshield Features & Benefits

- US Patent # 4,848,437

- Eliminates Contamination

- Increases Profits

- Easy Installation

- Quick Access to the mold

- Movable to Other Presses

- Reduces Scrap

- Can Be Used on Multiple molds

- Size : 6-11 ~ 20-32

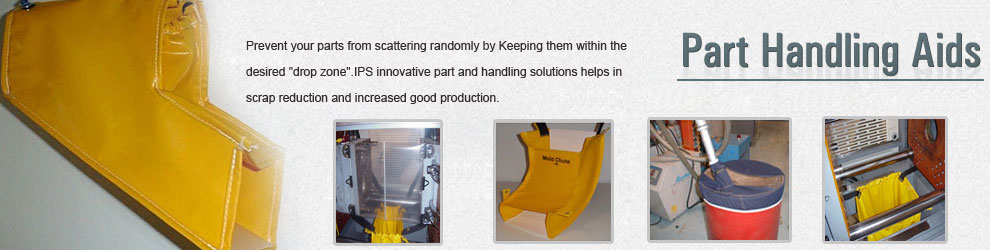

IPS Mould Shields™ stop your parts from scattering randomly within the mould open space by keeping them within the desired “drop zone”.

Daily use Ancilaries : - Hopper Magnets I Micro Torch I Industrial Hoses I Hand Pliars I Butane Gas Refillers I Lifting Accessories I Conveyors I Standard Tooling Parts

Machine Spares : - Linear Scales I Nozzle & Band Heater I Mould Clamps I Hydraulic Valves I Hydraulic Couplers I Mould Shield I Mould Chutes I HRTC Connectors

Mould Cooling :- Water Manifolds I Stainless Steel Manifolds I Alloy Manifolds I MTC Manifolds I Water Battery I QRC I Quick Couplers I Quick Connectors I

Purging Compounds : - Injection Moulding Grade I Extrusion Grade I Blow Moulding Grade I Ultra Purge I High E I 5060 I Low E I PET-E I PO I 5050 I ME-C I 9015

Machine Spares : - Linear Scales I Nozzle & Band Heater I Mould Clamps I Hydraulic Valves I Hydraulic Couplers I Mould Shield I Mould Chutes I HRTC Connectors

Mould Cooling :- Water Manifolds I Stainless Steel Manifolds I Alloy Manifolds I MTC Manifolds I Water Battery I QRC I Quick Couplers I Quick Connectors I

Purging Compounds : - Injection Moulding Grade I Extrusion Grade I Blow Moulding Grade I Ultra Purge I High E I 5060 I Low E I PET-E I PO I 5050 I ME-C I 9015

Group Sites !

www.novanativesafety.com

www.watermanifolds.net

www.purgingcompounds.co.in

www.industrialmart.in

www.novanative.com

www.novanativesafety.com

www.watermanifolds.net

www.purgingcompounds.co.in

www.industrialmart.in

www.novanative.com