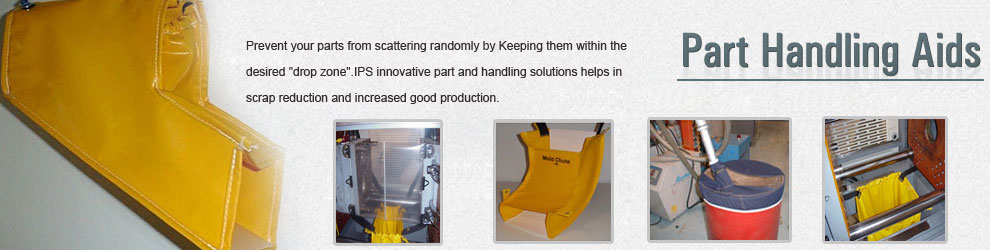

Mould Chute

Code:PS-3468

-

Mould Chute Features & Benefits

- Eliminates Contamination

- Increases Profits

- Easy Installation

- Movable to Other Presses

- Reduces Scrap

- Can Be Used on Multiple Molds

Mold Chutes stop your parts from scattering randomly in the “drop zone”. Mold Chutes ensure your parts land on your conveyor or in your packing case and not on the floor.

Mold Chutes are made of durable plastic with a PVC lining in the bottom to protect even the most delicate molding. The unique construction will not absorb oil or grease and is abrasion, puncture, and tear resistant. Each Mold Chute is easily cleaned using simple household cleaners and there are no concertina folds to trap moldings or dirt. Mold Chutes come in 18 standard sizes with in-line or side exit delivery chutes. Straight and Tapered Mold Skirts are available when you need to direct parts down onto a conveyor or into a box. The unique design of the right angle mold chute lets it attach to each mold half. As the mold opens and closes, the mouth of the chute opens and closes providing better protection from contaminants while the mold is closed. Conversely, In-line mold chutes are attached to the press frame and are static. An optional single Mold Shield can be attached to the chute and the movable mold half which will cover the chute opening providing protection from part contamination. All Mold Chutes can be attached to the machine using either magnets or custom support harnesses. Velcro straps allow precise adjustment of the chute to prevent loss of parts from uncontrolled ejection's.

Machine Spares : - Linear Scales I Nozzle & Band Heater I Mould Clamps I Hydraulic Valves I Hydraulic Couplers I Mould Shield I Mould Chutes I HRTC Connectors

Mould Cooling :- Water Manifolds I Stainless Steel Manifolds I Alloy Manifolds I MTC Manifolds I Water Battery I QRC I Quick Couplers I Quick Connectors I

Purging Compounds : - Injection Moulding Grade I Extrusion Grade I Blow Moulding Grade I Ultra Purge I High E I 5060 I Low E I PET-E I PO I 5050 I ME-C I 9015

www.novanativesafety.com

www.watermanifolds.net

www.purgingcompounds.co.in

www.industrialmart.in

www.novanative.com